The Best Way to Meter Low Flow Applications Part 2

Please take a look at part one of our previous blog before continuing on to read the second part. In exploring the benefits and disadvantages of different technology’s approach to metering low flows, it makes it clear which meters are the best selections.

Positive Displacement Meters

While positive displacement meters excel at metering low flows of viscous fluids, their resolution can be very low. When metering low flows of aqueous solutions, the “slip” past of the various moving elements is much greater than the volume being measured, making it a poor choice. There are a few positive displacement meters that have high precision, but these are both expensive and fluid specific.

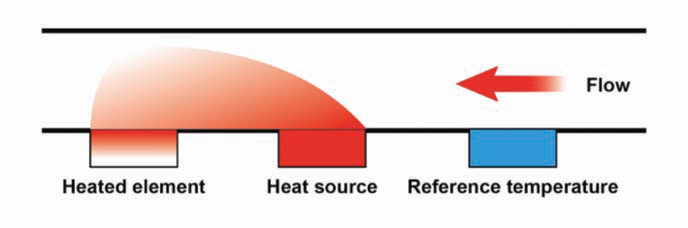

hermal Meters

Often offering good performance for metering low flows, thermal meters are much different than the previous technologies that were explored. These meters inject energy into the system so that the meter isn’t as reliant on the dynamics of the fluid for making the measurement. While still fluid-specific, they rely on the fluid’s thermal transfer properties. A downside of this device is that they usually have a slow response time.

Often offering good performance for metering low flows, thermal meters are much different than the previous technologies that were explored. These meters inject energy into the system so that the meter isn’t as reliant on the dynamics of the fluid for making the measurement. While still fluid-specific, they rely on the fluid’s thermal transfer properties. A downside of this device is that they usually have a slow response time.

Electromagnetic Meters

Much like the thermal meters, electromagnetic meters also do not rely on the moving fluid for performance. Instead, as a velocity-measuring device, they rely on an induced voltage in a moving conductor: the fluid. They are unable to work with non-conducting fluids; therefore, a vast number of liquids are ruled out of their measurement capabilities.

Much like the thermal meters, electromagnetic meters also do not rely on the moving fluid for performance. Instead, as a velocity-measuring device, they rely on an induced voltage in a moving conductor: the fluid. They are unable to work with non-conducting fluids; therefore, a vast number of liquids are ruled out of their measurement capabilities.

Coriolis Meters

Some manufacturers have introduced Coriolis meters into their product ranges, as they are very sensitive and are able to record low mass flows accurately. Unlike the preceding thermal and electromagnetic meters, this type does require the movement of the fluid to react with an energy input from the system. Unfortunately, these devices are very expensive as compared to other technologies.

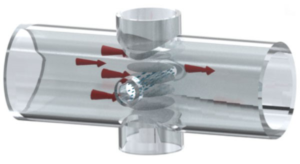

Ultrasonic Meters

As the newest addition to the low flow metering armory, ultrasonic meters are an innovative solution due to their ability to make ultrasound travel within the fluid via a small pipe over a long distance. In the last ten years, Titan has developed several generations of ultrasonic low flow flowmeters. These flowmeters use a time-of-flight design that is patented and capable of measuring the velocity of fluid within the pipe. The extremely high signal to noise ratio from these meters has been widely shown to enable metering of very low flows with immense precision.

As the newest addition to the low flow metering armory, ultrasonic meters are an innovative solution due to their ability to make ultrasound travel within the fluid via a small pipe over a long distance. In the last ten years, Titan has developed several generations of ultrasonic low flow flowmeters. These flowmeters use a time-of-flight design that is patented and capable of measuring the velocity of fluid within the pipe. The extremely high signal to noise ratio from these meters has been widely shown to enable metering of very low flows with immense precision.

Through the layout of these many devices, we are able to acquire both the benefits and disadvantages that they pose for the metering of low flows. JLC International is available to continue the conversation and illuminate any more details that are needed to further explore this topic. They also are able to answer any inquiries about dew point sensors or humidity transmitters and can further discuss ultrasonic flowmeters for other applications or inline flow meters. Please contact us with comments or questions by calling 1-888-358-2518.