Applications for Liquid & Gas Turbine Flowmeters

Overview of Turbine Flow Meters

A turbine flow meter is a sophisticated device that measures the volume of liquids or gasses as they pass through the turbine’s housing. The flow of liquid or gas causes the turbine’s freely-suspended blades to spin, with the velocity of the rotor being directly proportional to the velocity of the liquid or gas passing through the device. The pick-off mounted on the exterior of a turbine flow meter senses each rotor blade passing, then generates a frequency output, which is directly proportional to the volume of the liquid or gas. The rotational speed of the turbine rotor can be measured by a magnetic or modulated carrier (RF) pickup.

Industrial Applications

Turbine flow meters are utilized by the following major industries, and more, in the United States and around the world:

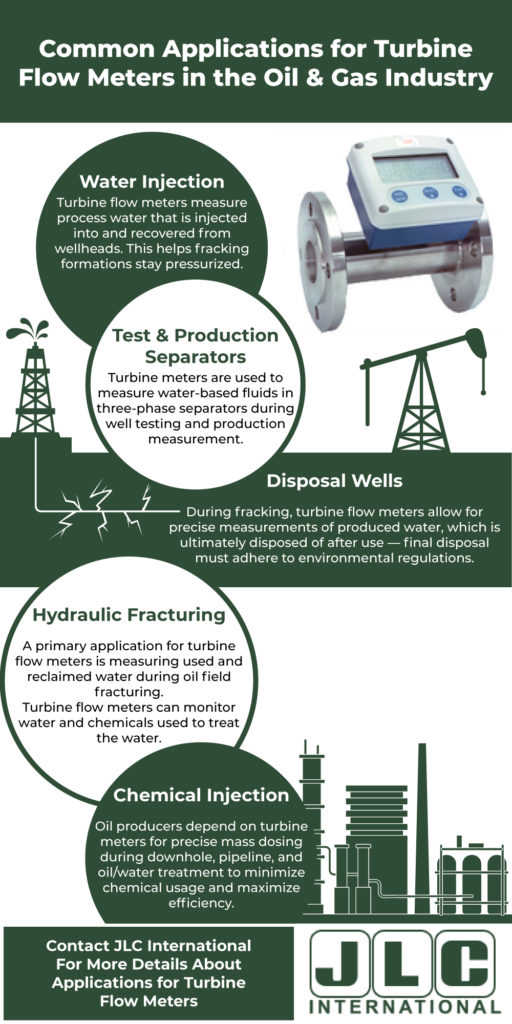

- Oil & Gas

- Aerospace Engineering

- Military

- Pharma & Biotech

- Food & Beverage

- Energy

- HVAC

- Cryogenics

- Industrial & Municipal

Many of these industries also utilize inline flow meters, which can be used in fuel cells, lab testing, and much more.

Product Specifications

To learn more about turbine flow meters and their various components, download the product data sheets listed below:

Gas Turbine Flow Meter in Stainless Steel GL Flow Series Gx: Suitable for measuring both inert and flammable dry gases and designed to operate at line pressures as low as 0.01 bar (0.2 psi). Totalizers can be mounted directly onto the turbine or fitted remotely.

Liquid Turbine Flow Meter in Stainless Steel GL Flow Series LX: Capable of meeting the demand for most liquid measurement applications. We also offer LX Turbines that are suitable for Hazardous Installations, available with optional Intrinsically Safe Variable Reluctance Pick-up, according to ATEX Ex ia IIC T6 to T3. Totalizer can be mounted on the Turbine or placed remotely

Digital Totalizer / Flow Rate Indicator GL Flow Series 101: The operator can easily use a preset batch value and execute repeated batches. Preset batch values, batched quantity, and units of measurement are displayed on the totalizer during each batch run. An overrun correction ensures accurate batch quantities. The running batch quantity (5/8” digits) can be programmed to count down or up.

Contact JLC International Today for Additional Information About Turbine Flow Meters.