Time-of-Flight Flowmeter Measurement

JLC International provides a variety of temperature, moisture, and flow metering instrumentation to meet the needs of the many industries who require accurate readings pertaining to flow travel. JLC International offers regular flowmeters, ultrasonic flowmeters, dewpoint sensors, temperature and humidity sensors, and also offers instrumentation for detecting and measuring moisture in oil, air velocity, carbon dioxide, and even handheld multi instruments.

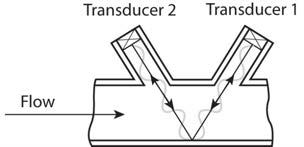

There are several types of ultrasonic meter technologies to choose from, but as JLC International and Titan Enterprises specialize in low flow metering using “time-of-flight” measurement, we will be focusing on this measurement principle for today’s article. Commercially, both clamp-on and bespoke low flow flowmeters are available. These use signals transmitted across the pipe diagonally, and in the case of a clamp-on flowmeter, a reflected signal. It may seem complicated at first glance, but the principle of time-of-flight measurement is very simple. Using this technique, sound is injected into the tube in the same direction the fluid is traveling. This injected sound will arrive sooner than flow traveling against the fluid flow. The difference is a direct function of the fluid velocity.

There are several types of ultrasonic meter technologies to choose from, but as JLC International and Titan Enterprises specialize in low flow metering using “time-of-flight” measurement, we will be focusing on this measurement principle for today’s article. Commercially, both clamp-on and bespoke low flow flowmeters are available. These use signals transmitted across the pipe diagonally, and in the case of a clamp-on flowmeter, a reflected signal. It may seem complicated at first glance, but the principle of time-of-flight measurement is very simple. Using this technique, sound is injected into the tube in the same direction the fluid is traveling. This injected sound will arrive sooner than flow traveling against the fluid flow. The difference is a direct function of the fluid velocity.

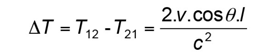

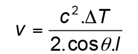

The transit time difference between the upstream and downstream waves is given by:

(1)

Where:

ΔT – is the difference in the transit times;

T12 – is the propagation from transducer 1 to transducer 2;

T21 – is the propagation from transducer 2 to transducer 1;

v – is the average axial velocity measured along the beam;

θ – is the angle between the direction of propagation and the pipe axis;

l – is the length of the path over which the integration is made and

c – is the speed of sound in the fluid

Thus, resolving the equation:  (2)

(2)

Once the average velocity is measured along the beam, it is then used to compute the average velocity across the cross-section of the channel and hence the flowrate of the fluid through the channel.

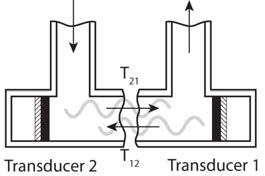

For smaller tube diameters, there are three basic ultrasonic flowmeter configurations.

This is similar to the example above, but the path is reflected off the opposite side of the conduit to double the path length and thereby increase flowmeter resolution.

An alternative arrangement (right) where the signal is purely axial. There is unnecessary turbulence around the change in direction which varies with flow and can upset the ultrasound transmission.

This system below uses 45° “reflectors” in the fluid path to bounce the signal from perpendicular to horizontal in line with the flow. Again, the reflectors are actually in the flow and create turbulence depending upon the fluid Reynolds number.

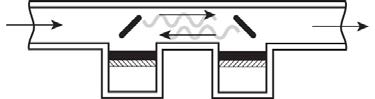

While all these designs have advantages, they also have shortfalls. As a consequence, Titan developed a patented low flow time-of-flight ultrasonic flowmeter design in which the signal is injected so that it travels purely axially without any reflections or disturbance to the fluid path (see below).

This arrangement gives very clean signals with little background noise. This improves both the accuracy and dynamic range of the meter. Because of the low frequency of operation, the sound in the fluid travels as a plain wave and is fully integrated at the point the signal is received. This reduces the effects of offset velocity profiles and viscosity. There are no “bounced” or secondary signals to distort the flow calculations.

For further information on Atrato ultrasonic flowmeter technology, please click here. To discuss a bespoke ultrasonic flowmeter optimized for your low flow application, please email JLC International. We also provide humidity sensors, dewpoint sensors, and a variety of other measuring instrumentation to meet the many needs of our customers. For more information, please call us at 1-888-358-2518. If you prefer we reach out to you, please fill out a contact form.