Breaking Down Differential Pressure (DP) Flow Meters Part 3 of 3

Before continuing, be sure to have read the last two parts of this blog in order to fully understand the many applications of Differential Pressure (DP) Flow Meters. Regardless of how long they have been around for, sometimes the latest technology isn’t always the greatest.

An In-depth Exploration of Differential Pressure Flow Meters

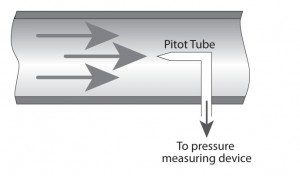

Pitot Tubes

Pitot tubes are most often encountered by the general public on the outside of aircrafts, wherein, they are used to measure the airspeed. In regards to industrial use, they are actually used in a wider variety of applications. They can be:

- Impact

- Cantilever

- Static

Each type also has a square law characteristic, like the orifice plate, generally. With very little pressure loss, pitot tubes are ideal for checking airflow in heating/cooling ducts or even large pipes with liquids. The disadvantage is that they use point measurement; a full tube traverse or a multi hole type should be used in an attempt to integrate velocities across the whole conduit.

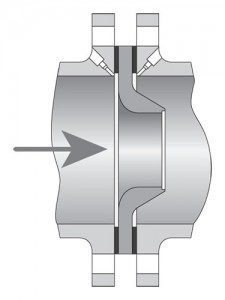

Venturi Tubes

For the orifice plate, flow lines create a contraction and expansion of the fluid. If the pipe resembles this shape, no secondary vortices are formed and there is no extra turbulence in the system. Being very energy efficient, this controlled flow does not impose high pressure loss on the system, as the flow is contracted and expanded slowly.

Nozzle Devices

Nozzle devices are an improved version of venturi tubes that was produced to have the simplicity of an orifice plate.

- Compact

- Inexpensive to produce (comparatively)

- Do not have a sharp edge, therefore can handle dirty fluids

- Corner taps are usually used

- Square root extraction is required

“Sonic Nozzles”

Used in certain applications of gasses, this variety of meter uses the characteristics of gasses to give a constant flow. They are extremely useful as a calibration reference because the throughput can be fixed if an upstream pressure is exceeded and the gas velocity in the throat is “sonic”.

Variable Aperture Devices

Disputed as a DP flow meter, these devices do use a differential pressure to make them work. However, their operation differs from those listed above.

- Pond filters use a meter of this type, with a hinged flap that opens when a mass of water hits it and the pressure drops.

- Rotameters also fall under this category. The height of the float or ball is driven by differential pressure that operates against gravity or even industrial versions of a spring.

In conclusion, Differential Pressure Flow Meters may be low-tech, but they are certainly reliable in any industry. With their measurement capabilities, they are the choice to make for durable and excellent applications. Contact JLC International for more information about our quality flow meters, such as our inline flow meter or our transmitters like our dew point sensor.