A Guide to Inline Ultrasonic Atrato Flowmeter Options

Ultrasonic flowmeters serve various purposes across numerous industries, including industrial, medical, food and drink, pharmaceutical, and others. At JLC International, we carry three different series of inline Atrato flowmeters from Titan Enterprises to meet the needs of most applications.

Here, we review the advantages shared by these products, as well as the differences between them, to help determine which solution is best for a given situation.

Benefits of Inline Ultrasonic Flowmeters

When measuring low flows, ultrasonic flowmeters are an ideal solution for many applications. They do not interfere with the flow, and they can measure virtually any type of liquid without being affected by the viscosity of the liquid. Additionally, they do not require liquid conductivity, and they have good downturns.

While small bore flowmeters have many challenges to overcome to achieve accurate readings, the Atrato ultrasonic flowmeters utilize a patented time of flight measuring system. In this system, both the upstream and downstream are measured; therefore, the velocity is equal to half of the difference between the two. The accuracy of this method is better than 250 picoseconds.

All the Atrato flowmeters feature a through bore design with no moving parts. With a fast response time and a high degree of reliability for better long-term results. Moreover, the simple design is easy to install, highly accurate, and cost-effective.

Comparing Inline Ultrasonic Flowmeters

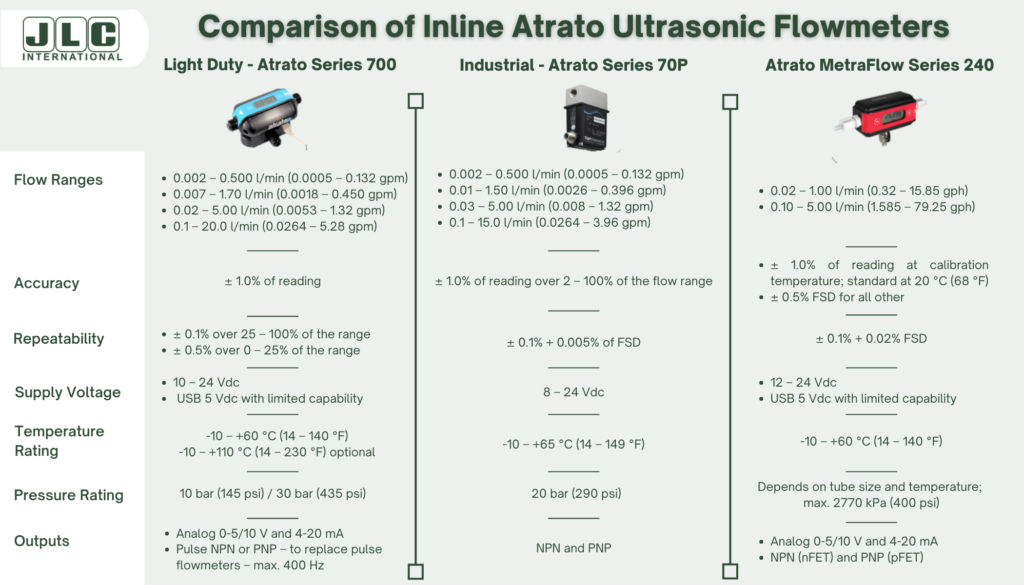

Below is a brief overview of some key specifications that are different between the three series of Atrato products, with additional details below:

Ultrasonic Light Duty – Atrato Series 700

The Atrato Series 700 is ideal for a wide range of low flow applications. Thanks to USB connectivity, users can directly connect to their laptops to monitor activity and change operating parameters within the software.

Ultrasonic Industrial – Atrato Series 70P

The Industrial Atrato Series 70P is designed to withstand more demanding outdoor conditions compared to the Series 700. The 316 stainless steel enclosure meets IP65 and NEMA 4X standards.

Chemical Inert Ultrasonic – Atrato MetraFlow Series 240

A key difference in the MetraFlow Series 240 is that it is made of Perfluoroalkoxy, or PFA, making the unit basically chemically inert. This makes it an ideal choice when working with aggressive chemicals.

Find the Right Ultrasonic Flowmeter for a Specific Application

To learn more about our ultrasonic flowmeters or for assistance with determining the best product for a specific application, contact JLC International online or by phone.