- Clamp-on sensors with no process interruption

- Non-invasive flow measurement of liquids

- Various transmitter mounting methods (wall mounted, 19″ rack, EEx housings)

- No pipeline disturbance, no pressure loss

- Suitable for most pipe materials with diameters from 6 mm to 6.5 m (1/4″ to 256″)

- Process temperatures from -30 °C to 200 °C (-22 °F to 392 °F)

- 1 to 4 flow channels and virtual calculation channels

- Sensors for use in hazardous areas

- Models for heat quantity (thermal energy) measurement

- Optional liquid sound velocity determination

- Multi Channel Ultrasonic FlowmeterConfigurable process inputs/outputs (0/4 … 20 mA, relay contacts, temperature, etc.)

- Multi-drop communication capabilities via RS 485

- Multi-language user interface

- Models with integral data logger

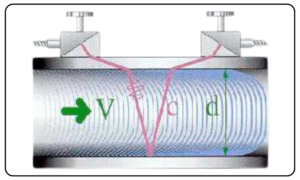

The range of non-invasive flowmeters utilizes ultrasonic technology for the accurate flow measurement of liquids in full pipes. The measurement of flow is based on the principle that sound waves traveling in the direction of flow of the fluid require less time than when traveling in the opposite direction. The difference in transit times of the ultrasonic signals is an indication for the flow rate of the fluid. For further information on the measuring principle, please click here. In permanent use The ultrasonic flowmeters are suitable for applications that require instruments for permanent installation. The flowmeters can be supplied with a variety of formats with different mounting methods in order to meet the demands of any application. Bringing processes under control All ultrasonic flowmeters feature extremely high measuring rates, DSP signal processing and comprehensive statistical evaluation of the raw data. Even under difficult measuring conditions, accurate and reliable measurements can be guaranteed. Now it is possible for the user to monitor processes where previously technical or economical factors prevented the use of non-invasive measurement techniques.

Ultrasonic Flowmeter for Hazardous Areas (ATEX)

Ultrasonic Flowmeter for Hazardous Areas (ATEX)

|

The economical solution Ultrasonic flowmeter as a single channel flowmeter in an IP 66 (~NEMA4X) dust and waterproof housing. |

|

Multi-channel field instrument Incorporating up to 4 flow channels and an array of process interfaces within an IP 65 (~NEMA4) field mounted enclosure or a 19 inch rack system. The housing has enough room to accommodate a variety of different configurations in order to meet diverse application requirements. |

|

Non-invasive flow meter suitable for hazardous areas An ultrasonic flowmeter for use in hazardous areas and rough industrial environments. This rugged flow meter features one or two flow channels and is fully ATEX certified for hazardous area Zone 1 and 2 applications. Serial communication facilities are for integration into plant wide control system |

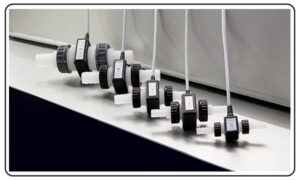

External measurement of internal flow The use of clamp-on sensors in conjunction with the flowmeters allows for both non-invasive measurement and easy installation. Unlike in-line devices, there is no need to use expensive materials for the measurement of aggressive media and what’s more, the risk of flanges causing leakages into the external environment is completely removed. Furthermore, by measuring non-invasively all measurements taken are fully independent of the pressure rating in the pipe. Additionally, there is no risk of contamination. Cost savings The ultrasonic sensors are clamped onto the outside of the pipe, thus eliminating the need to dismantle the pipe work and interrupt the process. The ultrasonic flowmeter can be applied to any type of standard pipe carrying clean or dirty liquids. Considerable installation cost savings can be achieved by using clamp-on technology. Also retrospective installations on existing pipelines are possible without great expense. Only two pairs of transducers cover virtually all pipe sizes thereby saving stock holding costs. Intelligent sensors! Each sensor pair is fully calibrated and has a non-volatile internal memory containing the calibration parameters, serial number and automatic sensor identification. Hermetically sealed stainless steel transducers and its associated cable conduit are suitable for rough industrial environments. User friendly All parameters can be entered via the keypad through a step-by-step interactive dialogue. With the clamp-on sensors positioned correctly, the flow rate of the liquid can be determined in minutes. High specification Fast digital signal processors and sophisticated signal analysis guarantee reliable measuring results even under difficult conditions where previously ultrasonic flowmeters had failed. Additionally, the units can be equipped with a number of optional functions: Integral data logger – Even without a strip-chart recorder or control system connected, all data is securely captured in the meter. This feature is ideal for stand-alone remote flow measuring stations or integrated telemetry solutions. Heat quantity measurement – Thanks to the integrated heat quantity measurement option in some models, it is additionally possible to measure the flow of thermal energy. The heat quantity coefficients for various media are already pre-programmed, thereby avoiding errors and guaranteeing accuracy. Concentration/density measurements – Concentration and density measurements can also be performed using clamp-on sensors. Ultrasonic flowmeters allow on-line product quality monitoring combined with the advantages of non-invasive measurement. Applications

External measurement of internal flow The use of clamp-on sensors in conjunction with the flowmeters allows for both non-invasive measurement and easy installation. Unlike in-line devices, there is no need to use expensive materials for the measurement of aggressive media and what’s more, the risk of flanges causing leakages into the external environment is completely removed. Furthermore, by measuring non-invasively all measurements taken are fully independent of the pressure rating in the pipe. Additionally, there is no risk of contamination. Cost savings The ultrasonic sensors are clamped onto the outside of the pipe, thus eliminating the need to dismantle the pipe work and interrupt the process. The ultrasonic flowmeter can be applied to any type of standard pipe carrying clean or dirty liquids. Considerable installation cost savings can be achieved by using clamp-on technology. Also retrospective installations on existing pipelines are possible without great expense. Only two pairs of transducers cover virtually all pipe sizes thereby saving stock holding costs. Intelligent sensors! Each sensor pair is fully calibrated and has a non-volatile internal memory containing the calibration parameters, serial number and automatic sensor identification. Hermetically sealed stainless steel transducers and its associated cable conduit are suitable for rough industrial environments. User friendly All parameters can be entered via the keypad through a step-by-step interactive dialogue. With the clamp-on sensors positioned correctly, the flow rate of the liquid can be determined in minutes. High specification Fast digital signal processors and sophisticated signal analysis guarantee reliable measuring results even under difficult conditions where previously ultrasonic flowmeters had failed. Additionally, the units can be equipped with a number of optional functions: Integral data logger – Even without a strip-chart recorder or control system connected, all data is securely captured in the meter. This feature is ideal for stand-alone remote flow measuring stations or integrated telemetry solutions. Heat quantity measurement – Thanks to the integrated heat quantity measurement option in some models, it is additionally possible to measure the flow of thermal energy. The heat quantity coefficients for various media are already pre-programmed, thereby avoiding errors and guaranteeing accuracy. Concentration/density measurements – Concentration and density measurements can also be performed using clamp-on sensors. Ultrasonic flowmeters allow on-line product quality monitoring combined with the advantages of non-invasive measurement. Applications

- Distribution and consumption measurements

- Chemical process flow monitoring

- Leak detection

- Ultra-clean liquid flow measurements

- Fresh water flow metering

- Effluent discharge measurements

- Accurate sewage and sludge flow measurements

- Non-conductive liquids

- Flow measurement of food products

- Remote flow measuring stations

- Measurement of aggressive and abrasive media

- Monitoring of coolant and heating circuits

- Liquid interface detection in pipelines

- Liquid type and quality identification

- Non-invasive concentration/density measurements

- Thermal energy flow measurements

- Dynamic flow event capturing